End-to-End Planning in a Post-Covid World

This Blog is the 2nd in a series of Blogs that explore the business case for a cohesive end-to-end plan for tomorrow’s retail environment.

Introduction

We know that we need an end-to-end plan, but what does that mean and why does it matter? Supply chain impact from Covid is entering its 18th month and the ripple effects could go on longer than anyone anticipated…a lot longer. In fact, a large C-Store Chain recently mentioned the challenges with trying to keep their stores in stock with basic beverage items. How do they plan to go forward?

Case Study

In this case study, the same convenience store chain’s sports drink replenishment order arrives. They typically get two different popular flavors per shipment, but today they only got one flavor. However, the quantity of flavor one is still what they would have gotten if the shipment contained both flavors.

The convenience store must put the product out but many of the missing flavors in the cooler are replaced by the one single flavor that was received. Customers come in to buy a drink and a snack and find their favorite flavor is missing. They could buy a different flavor, but many do not. In fact, they may not buy any drink at this store since they are not carrying their drink of choice.

This could also affect the snack purchase as the customer may want to try another store that may carry their drink choice and consolidate their purchase at the next store. This is a lost sale that can never be replaced. Why did it happen? The factory that produces flavor #2 had to close for two weeks due to Covid. This has consequences throughout the supply chain in cost, handling, availability and most importantly…trust in the supplier network.

The US food retail industry loses billions of dollars each year due to items that were out of stock or otherwise unsaleable. Since March 2020, that is only getting worse.

The need to adjust Level 1 processes to accommodate these unforeseen disruptions in the Supply Chain is critical.

Communication and collaboration between retailers and suppliers can greatly reduce these disruptions and provide visibility to an issue much sooner than it would normally take place.

Collaboration and Strategy Alignment

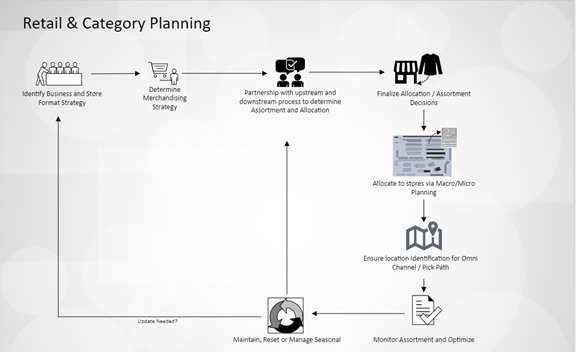

To have a cohesive end-to-end process, various parts of the supply chain and retail processes must align. Below are some examples of Level 1 Processes by department that can and should be aligned. The integration points need to be simple with easily recognizable check points and information/data exchanges that minimize downtime and roadblocks.

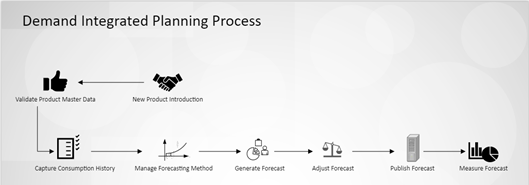

Demand Process

Assortments should be demand driven and the forecast should account for item substitutions, alternative suppliers, and market insight data. The adjustments can be made and published to alert others that are upstream and downstream that there are changes and what the details are. As demand changes in real time, the forecast can be updated and communicated.

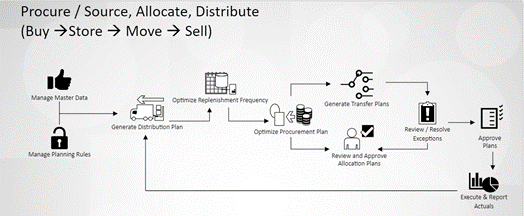

Supply Process

When adjustments are made to the demand forecast, they directly affect the supply process. There must be communication from demand to supply and from supply to retail. Ideally, there would be input communicated from supply back to demand and from retail back to supply. The integration points need to be simple with easily recognizable check points and information/data.

Retail Process

Feedback and communication from the retail team is critical to any supply and demand cycle as that is where the proverbial rubber meets the road. It is where supply literally meets demand and without a two-way communication process in place, many consumer habits and trends can go unnoticed.

Plantensive’s End-to-End Process

As Plantensive reimagined the Level 1 strategies, the Level 2 detail needed to be realigned and updated as well. Gaps that were now evident in the overall process were addressed by working through the step-by-step processes that make up each Level 1 Milestone. The altered retail landscape served as the basis to create a new strategy for each where it was necessary.

Up Next…Level 2 Processes

Look for our next blog in the series that will take a deeper dive into Level 2 processes, how they roll up to the new Level 1 points and provide guidance on navigating tomorrow’s rapidly changing retail landscape using tools that your organization may already possess.

Plantensive will also be hosting a webinar with the Category Management Association on this topic, “End-to-End Planning in a Post-Covid World” on Thursday, November 14th at 12:00 PM EDT. Register now!

Closing

We offer the business-critical skills and experience of a consulting force–when and how you need it. There are any number of reasons why your company might need an extra pair of (highly skilled) hands. When you do, we are ready to provide top talent to help your organization deliver crucial supply chain and retail initiatives. Whether you need one person or a team of technical and business solution experts, we are here to provide you with the right resources and guidance for your business needs.

To interact with the E2E process framework and match your technical and organizational factors for yourself, get in touch for a guided overview and complimentary copy. https://plantensive.com/contact/

Blog Authors: Bill Ackner & Todd McCourtie