End-to-End Planning in a Post-Covid World

This Blog is the 3rd and final in a series that explores the business case for a cohesive End-to-End plan for tomorrow’s retail planning environment.

Introduction

The supply chain disruptions that our industry has witnessed on a global scale over the past 18 months have been nothing short of incredible. Lead time on many items which were once predictable, or at least manageable, have become increasingly longer and more widespread. Out of stocks on everything from paper and cleaning supplies to meat and poultry have created a consumer climate of uncertainty that continues to undermine progress in restocking supply and returning consumers to more “normal” buying patterns. As items that have had supply issues return to store shelves, they are often scooped up by consumers in higher quantities and at a quicker pace. Sales are sales, but there is still a large group of consumers that are not able to purchase these products and have to make substitutions, or even a lifestyle change that completely eliminates the need for those items.

In this uneven and chaotic atmosphere, it becomes critical for retailers and suppliers to have a more flexible and agile plan for keeping their supply chain moving. This is where updating Level 2 processes to fit this new model becomes an integral part of planning for any organization and embracing the unique challenges of the supply and demand cycle in a post-Covid world.

The Breakdown

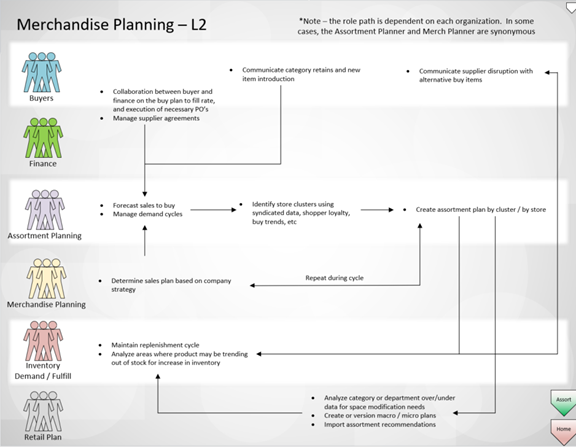

As we look at the Level 2 processes, we can see that they cannot be “business as usual”. Consumer insight data has become much more critical and real-time data and analytics is becoming a larger part of every-day business. The need to react and communicate quicker as new challenges arise seemingly out of nowhere needs to drive the “new look” Level 2 processes.

Large spikes and dips in supply across virtually all categories of retail have made historical data much less dependable and created more need for predictive tools and technologies.

Machine learning and real-time supply chain tools are seeing a spike in interest as they become a necessity for any organization who is attempting to smooth out the peaks and valleys in its supply chain metrics.

The retail industry must become much more predictive and agile. New trends, substitute items, transferability, and changing consumer shopping patterns all lead to a need for fundamental changes in the basic functions that make up most Level 2 processes.

For example, Merchandise Planning L2 will certainly need to adjust to this change in supply chain as forecasts may have to include longer lead times and the demand cycle analysis may change drastically due to long and short-term out of stocks. Each step in the process must have visibility to supply disruptions (out of stocks) and move quickly to identify substitute items and ascertain their availability and whether that availability meets the consumer need’s timeline.

It’s all interconnected and if the silos (that we talked about in the 1st blog in this series) are still in place, the new plan is most likely destined for failure due to delays and misunderstandings in the communication process.

The Roll-Up

So, what is the plan? Level 1 Demand, Supply and Retail Process are all dependent on the information flow and product needs that are determined in the Level 2 processes. Having clear points of intersection in the processes is as important as the tools and strategies that are applied to each. Here are a few examples of Level 2 processes that will roll up to support the overarching Level 1 processes.

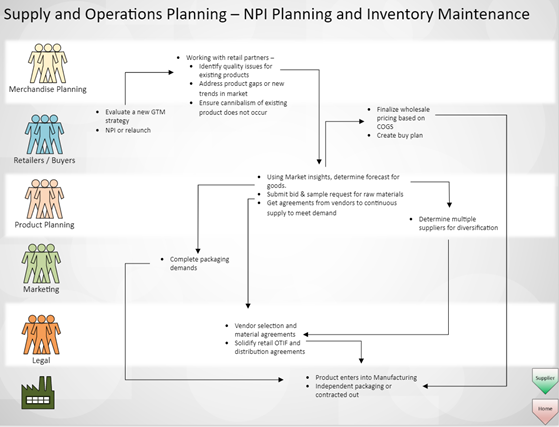

Supply and Operations Planning

This is where new and innovative Go-to-Market (GTM) Strategies are identified which include current inventory maintenance and New Product Introductions. Once these new strategies are developed, it is imperative that they are communicated to the other departments that will source, order, deliver and execute at store level. Not only are the strategies reimagined, but also the communication tools and processes used in getting the information out quickly and efficiently.

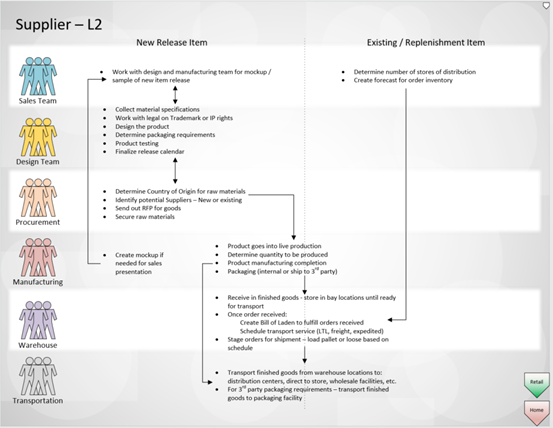

Supplier L2

The first and most critical step in the process. Can the supplier navigate the supply chain disruptions effectively enough to support the new GTM Strategies? Do they have the necessary and latest industry tools to support a newer, more agile approach?

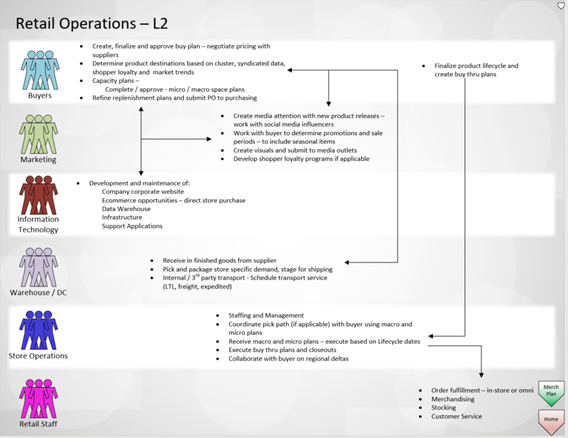

Retail Operations L2

Retail Operations perform many of the critical functions of planning for the ordering and delivery of the products that support the GTM Strategy. This is a multi-level division and communication process. Also, the communication between departments within this division is critical and should ultimately lead to a clear and concise plan to be passed on to the other areas.

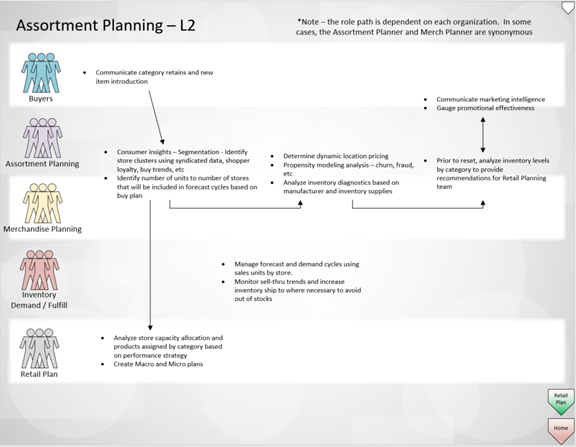

Assortment Planning L2

Assortment Planning will convert the GTM strategy into an actionable plan that can then be converted by Space Planning or Floor Planning departments into planograms and schematics, that will ultimately be used downstream by the Retail Execution team.

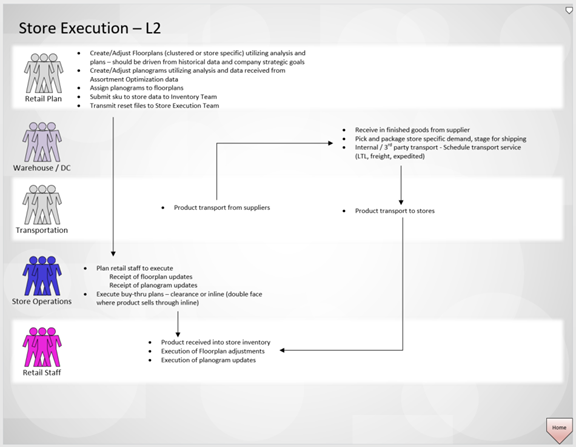

Store Execution L2

All the planning and communication ends up here, with the Store Execution team. Space Planners and Floor Planners will take the GTM Strategies, assortments, marketing strategies, demand and inventory plans and create the tools that are needed to create the in-store reality that should align with the vision of the overall organization.

Plantensive’s End-to-End Process

As Plantensive reimagined the Level 1 strategies, the Level 2 detail needed to be realigned and updated as well. Gaps that were now evident in the overall process were addressed by working through the step-by-step processes that make up each Level 1 Milestone. The altered retail landscape served as the basis to create a new strategy for each where it was necessary.

Up Next…CMA Webinar October 14, 2021 at 11:30am ET

Register now and join us as we put it all together and discuss what an End-to-End process looks like in a post-Covid world. We will talk about how Plantensive can help design the processes and determine which tools and strategies that Retailers and Suppliers can implement that can transform their siloed Supply Chain Process into a coherent, cohesive End-to-End Supply Chain process.

We offer the business-critical skills and experience of a consulting force–when and how you need it. There are any number of reasons why your company might need an extra pair of (highly skilled) hands. When you do, we are ready to provide top talent to help your organization deliver crucial supply chain and retail initiatives. Whether you need one person or a team of technical and business solution experts, we are here to provide you with the right resources and guidance for your business needs.

To interact with the E2E process framework and match your technical and organizational factors for yourself, get in touch for a guided overview and complimentary copy.

Blog Authors: Bill Ackner & Todd McCourtie